Electric idle makes work trucks more efficient, clean

Alabama Power employee Kevin Sanderson is pictured next to a company vehicle. With this new technology, Alabama Power becomes the first electric utility in the nation to use this feature which will simultaneously reduce engine emissions and fuel usage on bucket trucks and customer service vehicles.

Fleet owners are revved up over a Cullman company’s technology that makes it cleaner and cheaper when trucks operate in idle mode.

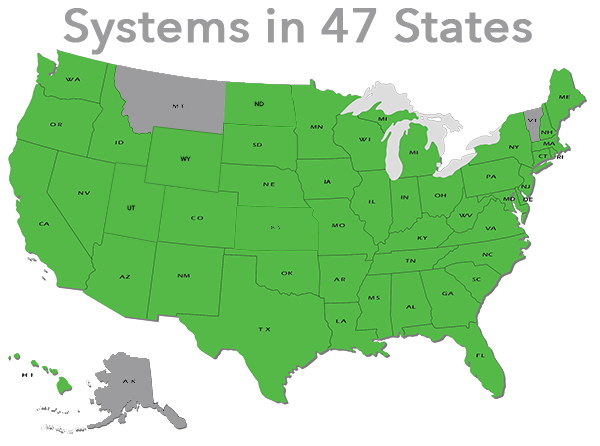

Alabama Power is the first electric utility in the nation to roll out a new technology on bucket trucks and customer service vehicles that simultaneously reduce engine emissions and fuel usage.

The new technology is manufactured by Zero RPM in Cullman. Alabama Power has installed the Zero RPM system that electrifies a truck’s functions – saving hours of unnecessary idle time each day. The system works by automatically shutting off the engine when the truck is parked. This idle mitigation system will also automatically start the truck engine when the driver is ready to roll.

ZeroRPM’s Idle Mitigation System uses a lithium ion battery pack to provide electricity that powers all truck accessories.

“Alabama Power has had our product in the field for almost a year now, Lance Self, CEO of Zero RPM, said. “They pioneered this technology within the utility industry. We appreciate their support and participation very much.”

ZeroRPM’s Idle Mitigation System uses a lithium ion battery pack to provide electricity that powers all the truck accessories, just as though the truck engine was idling. It can also provide enough engine-off power to run a bucket truck and the heating & air conditioning system that provides climate control through the factory vents.

The system also provides a quiet work environment while working in residential areas and allows linemen to communicate better without having to shout over a diesel engine while in the field.

“These trucks are, in effect, mobile offices for these guys,” said Danny Kings, fleet engineer for Alabama Power, who is leading the effort. “To allow our employees to do the same job with the engine not running saves fuel and reduces emissions. This process happens automatically, which is new to our industry. Rather than an engine running 10 hours a day, I’m seeing them run four to five hours with idle mitigation.”

Fleet egineer Danny Kings is joined by Lance Self, CEO of Zero RPM. “These trucks are, in effect, mobile offices for these guys,” said Kings.

The equipment adds 150 pounds to a typical truck and is one-third the size of a tool box.

“I’m particularly proud of the Fleet Services team for thinking outside the box, to be the first utility in the country to adopt this concept. This will reduce the amount of gas or diesel fuel burned in our work trucks,” said Don Scivley, Alabama Power vice president of Corporate Services. “We think it’s a win-win proposition. Not only are we reducing the company’s operating expenses, we are also improving our customer service and providing a safer work environment for our employees.”

The system has been installed on 14 Alabama Power trucks that are in use throughout the company’s service territory.

“This is exciting innovative technology that helps us better serve our customers while reducing our environmental footprint through lower vehicle emissions,” said Matt Bowden, vice president of Environmental Affairs for Alabama Power.